The Benefits of Using a Plastic 3D Printing Service

Manufacturing has changed dramatically over the past decade, and businesses can’t ignore the revolutionary impact of additive technology. Traditional production methods often involve lengthy setup times, expensive tooling, and significant material waste that eats into profit margins. Modern manufacturing demands faster turnarounds, lower costs, and greater design flexibility than ever before.

Companies across every industry are discovering that partnering with professional providers offers unprecedented advantages in speed, cost-effectiveness, and design freedom that simply weren’t possible with conventional manufacturing approaches.

Cost-Effective Production Solutions Through 3D Printing Services

The manufacturing revolution through 3D printing offers clear advantages in speed and flexibility, but the most compelling benefit for businesses remains the dramatic cost reduction compared to traditional methods. The 3D printing market was valued at $ 12.6 billion in 2021 and is expected to reach 34.8 billion by 2026, at a CAGR of 22.5% over the forecast period. This explosive growth reflects businesses’ recognition of substantial cost savings.

When it comes to production economics, 3d printing companies have completely changed the landscape by reducing the need for significant upfront investments. By choosing a plastic 3d printing service, businesses bypass the need for expensive injection molds, custom tooling, or tying up capital in large minimum order quantities.

Eliminating Traditional Manufacturing Overhead

Traditional manufacturing burdens businesses with hidden costs that often exceed the actual production expenses. Setup fees, tooling costs, and inventory storage can quickly spiral into thousands of dollars before you’ve even produced a single part.

Rather than requiring the creation of costly tooling or warehouse storage, using an online 3d printing service allows you to upload your design, select preferred materials, and receive your parts within days, sometimes hours.

Transparent Pricing Models for Budget Planning

Companies can take advantage of 3d printing service online platforms that provide instant quoting, offering real-time price calculations based on your specific requirements. This ensures you understand costs upfront, removing unexpected budget issues associated with traditional projects.

Volume-Based Cost Optimization Strategies

With custom 3d printing services, you have the flexibility to order both prototype quantities and larger production runs without dramatic per-unit price changes, a stark contrast to traditional manufacturing, where small batches can be prohibitively expensive.

Advanced Material Selection for Optimal Performance

Beyond the impressive cost savings of up to 70% compared to traditional manufacturing, the true power of modern 3D printing services lies in their extensive material libraries that don’t compromise performance for affordability. Today’s plastic options range from basic prototyping materials to high-performance engineering polymers that rival traditionally manufactured components.

High-Performance Engineering Plastics Available

Advanced engineering plastics like PEEK, PEI, and carbon fiber-reinforced materials offer exceptional strength-to-weight ratios. These materials withstand extreme temperatures, chemical exposure, and mechanical stress while maintaining dimensional stability throughout their service life.

Biocompatible and Medical-Grade Material Options

Medical applications demand materials that meet strict biocompatibility standards. USP Class VI certified plastics enable the production of surgical guides, prosthetics, and medical devices that safely interact with human tissue.

Sustainable and Recycled Plastic Alternatives

Environmental consciousness drives material innovation in additive manufacturing. Recycled plastics and bio-based polymers reduce environmental impact without sacrificing performance characteristics.

Rapid Prototyping and Time-to-Market Acceleration

The ability to receive prototypes within hours rather than weeks fundamentally changes how designers approach product development, but the real breakthrough comes from the geometric possibilities that 3D printing unlocks. Despite the high initial setup costs associated with 3D printing machines, AM-produced goods remain less expensive than those manufactured through traditional processes.

Same-Day and Express Manufacturing Options

Leading providers offer express services that can deliver parts within 24 hours. This rapid turnaround enables iterative design processes where engineers can test, modify, and retest concepts in real time.

Iterative Design Testing Capabilities

Traditional manufacturing makes design changes expensive and time-consuming. Additive manufacturing encourages experimentation by making design iterations cost-effective and quick to implement.

Global Distribution Network Access

Many providers maintain production facilities worldwide, enabling local production that reduces shipping times and costs while supporting just-in-time manufacturing strategies.

Design Freedom and Complex Geometry Capabilities

Creating complex internal lattice structures and multi-part assemblies might seem to compromise quality control, but leading 3D printing services have developed rigorous standards that enhance precision and consistency. Traditional manufacturing constraints simply don’t apply when working with professional providers.

Lattice Structures and Internal Geometries

Additive manufacturing creates internal structures impossible with traditional methods. Hollow chambers, integrated cooling channels, and complex lattice work reduce weight while maintaining strength.

Multi-Part Assembly Printing

Single-print assemblies eliminate assembly time and reduce part counts. Moving mechanisms can be printed as complete, functional units that require no post-assembly.

Overhang and Support-Free Design Optimization

Advanced printing techniques minimize or eliminate support materials, reducing post-processing time and material waste while enabling more complex geometries.

Quality Assurance and Professional Standards

ISO-certified processes and dimensional accuracy within ±0.1mm demonstrate that 3D printing services can match traditional manufacturing quality, but can they handle increasing production volumes effectively? Professional providers implement comprehensive quality systems that ensure consistent, repeatable results across all production runs.

ISO-Certified Manufacturing Processes

Leading providers maintain ISO 9001:2015 certification, ensuring consistent quality management throughout the production process. These standards guarantee traceability, documentation, and continuous improvement protocols.

Dimensional Accuracy and Tolerance Control

Modern equipment achieves tolerances rivaling traditional manufacturing. Layer heights as fine as 0.05mm enable smooth surface finishes and precise dimensional control for critical applications.

Material Testing and Certification Documentation

Professional services provide material certificates and testing documentation that verify mechanical properties, ensuring parts meet specified performance requirements.

Industry-Specific Applications and Case Studies

From single prototypes to thousands of parts through on-demand production, these scalable solutions have already transformed specific industries in remarkable ways. Examining real-world applications across automotive, healthcare, aerospace, and consumer electronics reveals the practical impact of these manufacturing capabilities.

Automotive Component Manufacturing

Automotive engineers use additive manufacturing for custom tooling, end-use components, and rapid prototyping. Low-volume production runs become economically viable, enabling specialized parts and customization options.

Medical Device and Healthcare Applications

Healthcare applications range from patient-specific surgical guides to custom prosthetics. Biocompatible materials enable direct patient contact, while rapid production supports emergency medical needs.

Aerospace and Defense Part Production

Weight reduction drives aerospace adoption of additive manufacturing. Complex geometries reduce part counts while maintaining structural integrity, crucial for flight-critical applications.

Future Trends in Plastic 3D Printing Services

Multi-printing, hybrid manufacturing integration, and automated post-processing represent exciting possibilities for tomorrow’s manufacturing landscape, but today’s practical decisions require answers to immediate questions about costs, timelines, and capabilities. These emerging technologies promise even greater efficiency and capability.

Future systems will simultaneously print multiple materials, creating parts with varying properties throughout their structure. This enables embedded electronics, variable stiffness, and integrated functionality.

Combined additive and subtractive processes offer the best of both worlds: additive manufacturing’s design freedom with traditional machining’s surface finish and precision.

Making Smart Manufacturing Decisions

Businesses now have unprecedented flexibility, speed, and cost advantages thanks to the rise of plastic 3d printing service providers. The combination of cost reduction, design freedom, and rapid production capabilities creates opportunities that traditional methods simply can’t match.

Whether you’re developing prototypes or scaling production, these services offer the flexibility and efficiency modern businesses need. The question is whether you’ll embrace these advantages before your competitors do.

Common Questions About Plastic 3D Printing Services

Why is it important to be safe when using plastics in 3D printing?

Printers release volatile organic compounds and ultrafine particles during operation. These emissions vary significantly depending on materials like ABS or PLA, requiring proper ventilation and safety protocols.

How does plastic 3d printing work?

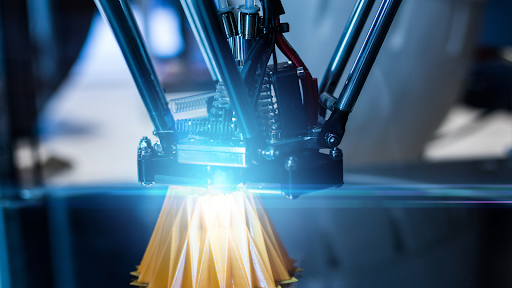

A heated moving head melts plastic filament, depositing it layer by layer in desired shapes. A moving platform lowers after each layer, building three-dimensional objects from digital designs.

What’s the typical turnaround time for custom projects?

Most services offer 2-5 business day standard delivery, with express options available for 24-48 hour turnaround depending on complexity and material requirements