The Role of Powder Filling Machines in Streamlining Manufacturing Processes

Fueling the ever-growing need for quality production in the realms of food, pharmaceuticals and chemistry entails a high level of efficiency and accuracy. This need is best addressed by highly sophisticated machines such as powder filling machines, that automatically take care of the filling procedures such as incorporating accurate measurements and optimizing production speed. In this article, we will discuss the significance of powder filling machines in addressing the challenges of the manufacturing process and why it is crucial to select the right automatic packaging machines manufacturers.

Defining the Steps Involved in Powder Filling Machines

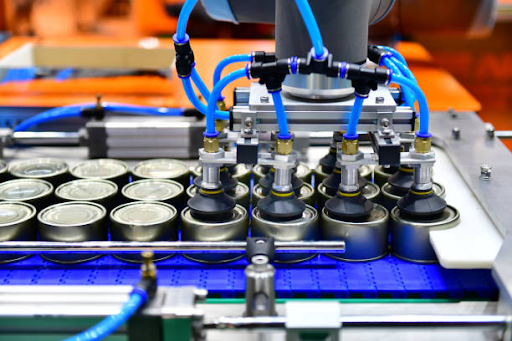

Whether it is powdered spices, oats, medicine, or even powdered chemicals, powder filling machines have the ability to dispense the precise amount of powder into suitable bottles, pouches, or jars. The basic powder filling procedure is generally standardized and consists of three steps; powder transfer, accurate dosage, and sealing the package. Each step is unique to the characteristics of the product as well as the quantity of powder that is to be filled in.

The best thing about a powder filling machine is that it saves a lot of time and prevents errors. With the aid of auger filling or volumetric filling, the machine makes sure every package is filled correctly. There are no product changes, little waste, and work is done in a shorter time frame. We, as a producer of these automatic packaging machines, know that an accurate automated process is essential for product integrity and the smooth operations of a business. This turns even more efficient when advanced solutions such as monitoring and system adjustments in real time are incorporated. These systems reduce human error, which ensures a greater product output, all while maintaining the high quality demanded by consumers. For the manufacturers, this greatly optimizes their expenses.

Enhanced Productivity at a Low Cost

The notable improvements in productivity with the use of powder filling machines benefit the customers greatly. By automating the powder filling process, businesses can significantly reduce the time and labor needed for filling and packaging. Manually filling products is not only labor and time intensive, but also inconsistent. Too much or too little filling can be done, both of which are harmful to business profitability. The ability to perform high-speed operations consistently is one of the most important advantages of automated systems.

The automatic powder filling machines are highly accurate with high speed operation. With large volumes of the product filled and packaged products in a short time, these machines further reduce downtime as well. For improved consistency, these machines also help achieve higher production targets, while maintaining proper ratios and doses during filling. Be it bulk containers or pouches, the machine’s flexibility is unparalleled. These are more suited for modern manufacturers as they are aimed at maximizing production output with further accuracy across batches. Adoption of these machines is protecting profits, operational costs, and improving competitiveness in a ever increasing market that demands cost effectiveness.

Powder Dosing Precision and Accuracy

The accuracy of dosage is essential in the production of powdered products. There is an adverse impact on the product roi, quality, and customer satisfaction when there are discrepancies in filling the desired doses. Advanced technologies are integrated in powder filling machines to allow for precise dosing. For example, some auger fillers employ a rotating screw to transfer a predetermined quantity of powder into the auger filler. These measurements are very precise and do not change from dose to dose which is termed as accuracy. Such accuracy allows manufacturers to eliminate costly mistakes and guarantees that every package is correctly filled.

Moreover, being able to adjust the real-time dispensation of powders enables manufacturers’ to remain compliant with regulations especially in the food and pharmaceuticals industries, where weight and dosage precision is fundamental. Developing and providing reliable dosing systems for automatic capsule filling machines is a priority for packagers because it enhances efficiency of production and improves the quality of end products. This minimizes waste and maximizes the profitability of manufacturers because filling doses are preset without excess. Dosing preciseness also ensures no risks of customer dissatisfaction with under-filled packages or inconsistent receiver quantities.

Improved Safety and Quality Of Products

Apart from the increased efficacy and accuracy of powder filling machines, such machines also improve the safety and quality of the product. In manual filling processes, there is increased risk of contamination either from the use of unclean equipment or the human element in the filling process itself. The use of automatic powder filling machines eliminates this risk as the filling process is completely automated and enclosed which reduces the chances of contamination and preserves the integrity of the product.

Moreover, many of these machines are equipped with self-contained quality control units that check for improperly filled packages and simply reject them. This means that only compliant products get to the customer, which helps to instill market confidence. As an automatic packaging machine manufacturer, the key elements in building machines that meet stringent industry requirements is the effectiveness of the filling process, safety, and reliability. The integration of advanced technologies such as sensors and real-time quality monitoring provides the highest level of product safety in the most sensitive industries like food and pharmaceuticals. Additional measures to enhance reliability in the filling process ensures that human error is minimized which increases consistency which helps to strengthen the brand’s quality reputation.

Conclusion

There are many purposes served by powder filling machines, one of them focusing on improving the efficiency of the entire organisation by increasing the level of accuracy and the quality of the product on offer. Picking the most appropriate powder filling machine for your business will definitely affect how your business functions, be it the food, pharmaceutical or chemical industry. At the same time, these devices assist industries in coping with the relentless demand from the market while sustaining the standard of quality in production. However, applying powder filling machines should only be done through the guidance of packaging automation specialists as these experts ascertain that the precise PR issues are met, marking out goals for the business. Once manufacturers are able to properly have the right machines that suit their business needs, they are able to drastically improve their level of productivity while achieving the highest level of requirements of quality and safety. It is essential that manufacturers enhance the efficiency of every aspect of the process to fulfill the market requirements and that the delivered products are of great quality.