How Preventive Maintenance Software Helps Businesses Avoid Costly Equipment Failures

Every business that relies on machinery, equipment, or facilities knows the frustration of unexpected breakdowns. One minute everything runs smoothly, and the next, a critical piece of equipment stops working. Production halts, employees stand idle, and repair costs pile up quickly. These situations happen more often than they should, and most of them could have been prevented with proper planning.

This is where preventive maintenance becomes essential. Instead of waiting for things to break down, smart businesses now use CMMS preventive maintenance software to stay ahead of problems. These systems help maintenance teams schedule regular checkups, track equipment performance, and fix small issues before they turn into expensive disasters.

Why Equipment Breaks Down Without Warning

Most equipment failures do not happen suddenly. There are warning signs that something is wrong, but busy maintenance teams often miss them. A machine might start making unusual noises, vibrations could increase slightly, or performance might drop just a bit. Without proper tracking and scheduled inspections, these early warnings go unnoticed until complete failure occurs.

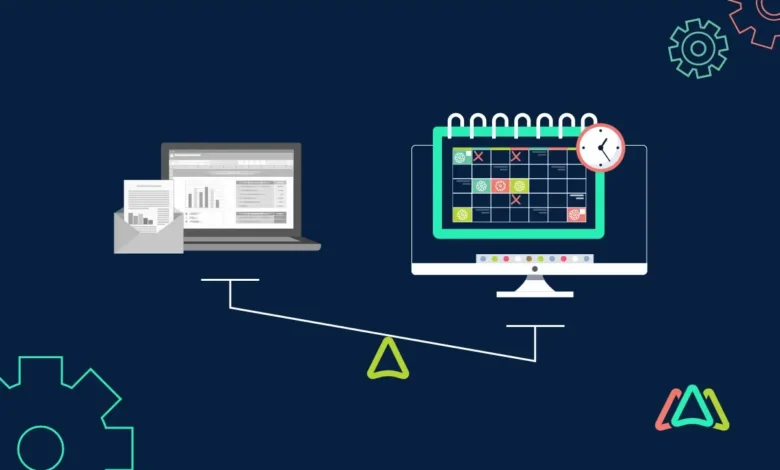

Traditional maintenance approaches relied on paper checklists, spreadsheets, and memory. A maintenance manager might remember that a pump needs checking every three months, but what about the fifty other pieces of equipment? Important tasks get forgotten, and by the time someone remembers, damage has already occurred.

The financial impact of reactive maintenance adds up fast. Emergency repairs cost more than planned maintenance. Rush shipping for parts increases expenses. Lost production time affects revenue. Employee overtime during emergency repairs strains budgets. When you add everything together, the total cost of reactive maintenance often runs three to five times higher than preventive approaches.

How Modern Maintenance Software Changes Everything

CMMS preventive maintenance software transforms how maintenance teams work. Instead of relying on memory or scattered notes, everything gets organized in one central system. Equipment information, maintenance history, spare parts inventory, and work orders all live in the same place.

The software automatically generates work orders based on schedules you set up. If a conveyor belt needs lubrication every two weeks, the system creates that work order without anyone needing to remember. Maintenance technicians receive notifications about upcoming tasks, so nothing falls through the cracks.

Tracking becomes much easier too. Every time a technician completes maintenance, they record what they did, how long it took, and what parts they used. Over time, this creates a detailed history for each piece of equipment. Managers can review this history to spot patterns, identify problem equipment, and make better decisions about repairs versus replacements.

MAPCON provides these capabilities to manufacturers and facilities teams across different industries. The platform helps organizations move from reactive firefighting to proactive maintenance planning, which saves money and reduces stress for everyone involved.

Real Benefits That Maintenance Teams Experience

When maintenance teams start using CMMS preventive maintenance software properly, several improvements happen quickly. First, equipment reliability increases noticeably. Regular inspections catch developing problems early. Small repairs prevent major breakdowns. Machines run more consistently and last longer.

Second, maintenance costs drop significantly over time. Planned maintenance costs less than emergency repairs. Technicians work more efficiently when they have scheduled tasks instead of rushing around putting out fires. Parts get ordered in advance at better prices rather than paying premiums for rush deliveries.

Third, documentation improves dramatically. Compliance requirements, warranty claims, and audits all become easier when you have complete maintenance records. If equipment fails under warranty, you can prove you followed the maintenance schedule. If inspectors arrive, you can quickly produce required documentation.

Safety also improves when equipment gets maintained properly. Well-maintained machines cause fewer accidents. Regular inspections identify safety hazards before anyone gets hurt. This protects workers and reduces liability risks for the company.

Getting Started With Preventive Maintenance

Implementing preventive maintenance does not need to be overwhelming. Start by making a complete list of all equipment that needs regular maintenance. For each item, determine what maintenance tasks are necessary and how often they should happen. Manufacturer recommendations provide good starting points for these schedules.

Next, prioritize your equipment. Some machines are more critical than others. A production bottleneck that stops your entire operation deserves more attention than a backup system. Focus your initial efforts on the equipment that has the biggest impact on your operations.

MAPCON helps organizations through this process by providing a structured way to organize equipment data, build maintenance schedules, and track completion. The software guides maintenance teams through setup and ongoing operations, making the transition to preventive maintenance smoother.

Training your team is also important. Maintenance technicians need to understand not just how to use the software, but why preventive maintenance matters. When they see how it makes their jobs easier and reduces crisis situations, they become advocates for the system.

Making Preventive Maintenance Work Long Term

Success with CMMS preventive maintenance software requires ongoing commitment. Someone needs to manage the system, review reports, and make adjustments based on what the data shows. If certain maintenance tasks consistently reveal no problems, perhaps the frequency can be reduced. If equipment keeps having issues despite scheduled maintenance, the approach might need modification.

Regular review of maintenance metrics helps identify improvement opportunities. Track statistics like mean time between failures, maintenance costs per asset, and work order completion rates. These numbers tell you whether your preventive maintenance program is working or needs adjustment.

Communication also matters. Maintenance teams should meet regularly to discuss what they are seeing in the field. Technicians often notice things that reports do not capture. Creating space for these conversations helps refine your maintenance approach over time.

The investment in preventive maintenance pays off through reduced downtime, lower repair costs, longer equipment life, and less stress for maintenance teams. Organizations that commit to this approach consistently report that they wish they had started sooner.

Making the switch from reactive to preventive maintenance represents a significant change, but the benefits make it worthwhile. With the right tools and commitment, any organization can reduce equipment failures and run more smoothly.